Lubrication

Water Trucks

Fluid Trans

Fuel & Evac

Why Choose Hyden as your Water Truck System provider?

Hyden is a distributor of all Major water truck component manufactures

Hyden is accepted by all Major OEM’s as a quality installer of spray systems

Hyden has a proven track record of providing outstanding after sale service and field service support

Hyden Engineering Water Truck Story Story

Hyden was appointed a distributor of Magnum and began selling and servicing these components. It was not long after this we noticed the significant technical difficulties customers were having with the user interface and water pump control offered from existing systems and we began designing a new system to provide users the ability to have ground speed propositional spraying and a simpler user interface and Enviropsray V0 was born. Following the success of our V0 system with over 250-system sold, continued R&D lead to the development of a new controller platform Omnicontrol V1 and its associated software Envirospray V1 being a touch screen system with 70% less wiring. Again, further R&D continued and this platform was updated to our current CAN bus system Omnicontrol V2 with this taking diagnostics and water control to a level no experienced before in mining. Now that we could control water flow and valve operation completely a new opportunity presented itself with the response rate of the spray heads and the development of SprayRight became the answer with its Spot-On rapid response opening and closing within 0.5-sec.

Since then, Hyden has continued to develop additional features to our system as listed below:

Fill point control with Auto Fill shut off

Integrated Fill point camera and reversing camera options on screen

Foam level monitoring on screen

Spray pattern lockout control

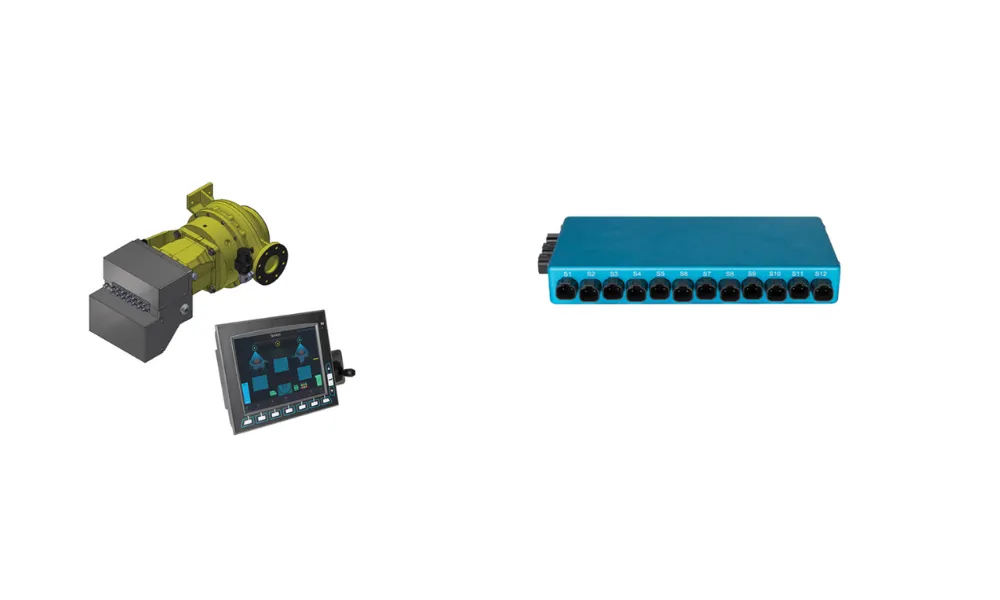

Envirospray V2 with Omncontrol technology

- Motor stroke adjusts to absorb total hoist pump flow, reducing hydraulic operating pressures

- System can control water pump speeds up to 3000 rpm, maximizing cannon and spray performance

- The system integrates with all major truck brands without changing the OEM hydraulic flow paths

Intuitive touch operation negates the need for detailed training manuals - 10.4” screen provides graphical feedback of system operation and performance

- OMNICONTROL® can control multiple systems from the one platform decluttering drivers cabinsControllers are certified IP6k9k are enclosed within aluminum housings and also guarded by SS covers or mounted within SS control boxes for maximum protection

- Each output has a dedicated plug with an associated input for full closed loop control

SprayRight Rapid Response Spray Heads

- Fail-Safe on system shutdown

- Rapid Response Enables 10m spot lengths at 50km/h

- Remains open under any water pressure, extending pump control range

- Two outlet heights

- Fully adjustable outlet width

- Flow naturally guided by body lip preventing unintended side spray

Akron Monitors and Nozzles

Hydraulic

- Hydraulic motor flow 1/2 gpm @ 500 psi

- Stainless construction

- 320° rotation

- 155° elevation (+90°, -65°)

- Fast travel, 20°/ sec

- Pressures up to 200 psi

- 2 1/2″ waterway (65 mm)

- Reaches 200′ at 750 gpm

Electric

- 12 or 24 volt motor

- Stainless Construction

- 320° Rotation

- 155° Elevation (+90°, -65°)

- Fast travel, 20°/ sec

- Pressures up to 200 psi

- 2 1/2″ Waterway (65 mm)

- Reaches 200′ at 750 gpm